Erreur de format d'e-mail

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

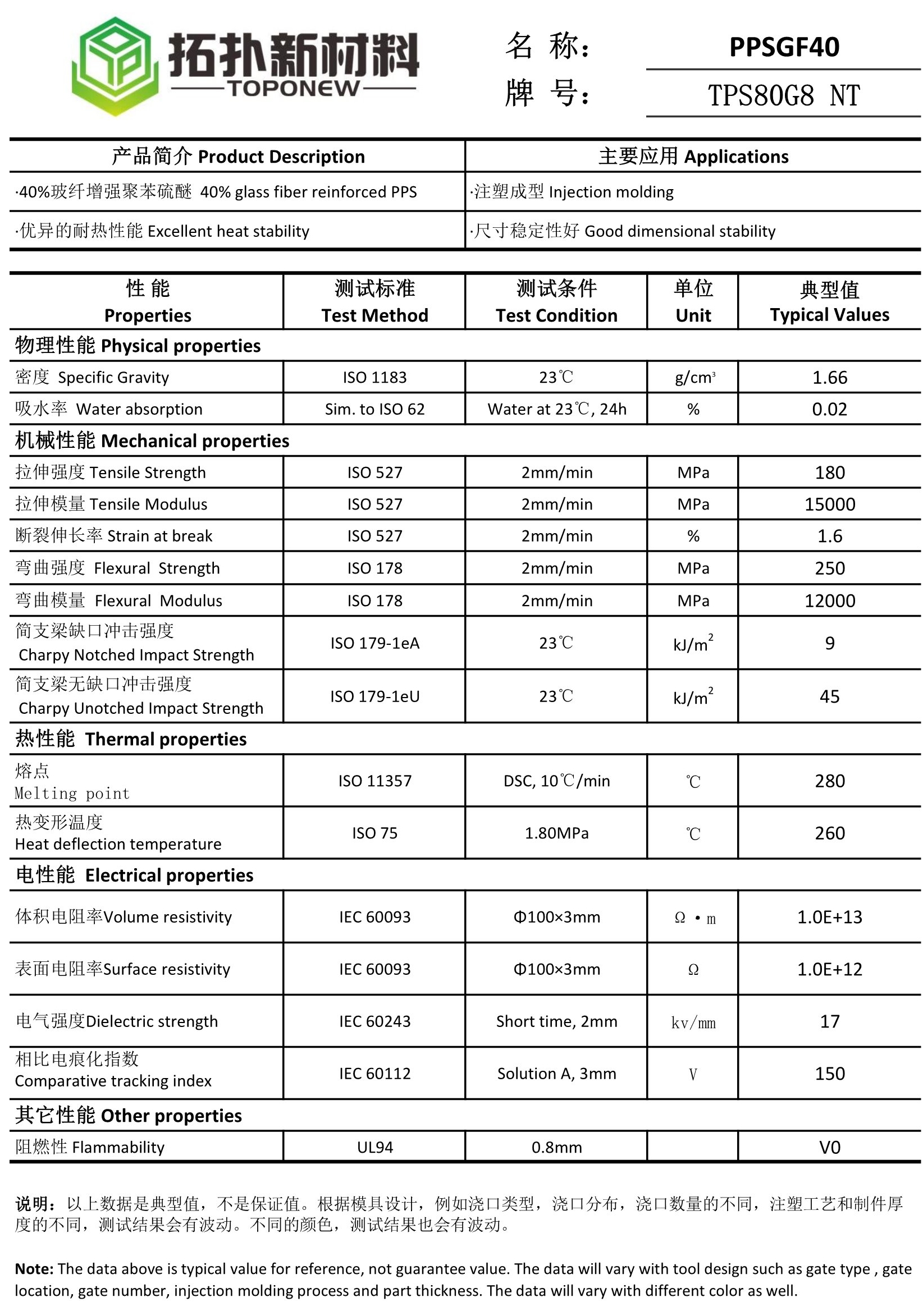

PPS GF40 TPS80G8NT

Glass Filled: 40%

UL94 0.8mm V0

(Custom materials available according to your Technical Data Sheet)

- Les détails du produit

-

Download

Customizable Materials Available:

- Color (Customization of plastic pellet color according to your requirements.)

- Flame retardant grade (Let us know which flame retardant level you need: 0.8mm-3.0mm HB, V0, V1, V2, 5VA, 5VB)

- Glass fiber reinforcement material (10%-50% availability)

- Carbon fiber reinforcement material (10%-50% availability)

- UV resistance property (Tell us the application scenarios or UV resistance level of the materials )

- Other materials can also be customized ( Just need to provide your Technical Data Sheet. )

Technical Data Sheet of PPS GF40 TPS80G8NT

PPS GF40 TPS80G8NT is PPS (Polyphenylene Sulfide) material reinforced with 40% glass fiber, ensuring enhanced mechanical strength and stability.

Our PPS GF40 TPS80G8NT granules meet the stringent UL94 V0 flame retardant rating at a thickness of 0.8mm, making them suitable for applications requiring fire resistance. Additionally, this product complies with RoHS environmental standards, guaranteeing its suitability for various industries.

Featuring excellent high-temperature resistance, dimensional stability, and outstanding resistance to creep deformation, PPS GF40 TPS80G8NT is an ideal choice for applications in the chemical, electronics, electrical appliances, and machinery sectors. Its remarkable chemical resistance ensures durability in harsh operating environments.

Furthermore, PPS GF40 TPS80G8NT offers excellent electrical insulation properties, making it suitable for electrical and electronic components that require reliable performance.

As a trusted Engineering Modified Plastic Manufacturer, we are committed to providing our customers with reliable and high-performance materials. By utilizing PPS GF40 TPS80G8NT, our customers can benefit from its superior flame retardancy, exceptional mechanical properties, and ease of processing, ensuring success in their application solutions. This material is widely used in various industries, including chemical, electronics, electrical appliances, machinery, and more, such as MCB operating mechanisms.

What does PPS mean material?

In the context of materials, when we refer to PPS, it typically stands for Polyphenylene Sulfide. PPS is a high-performance engineering thermoplastic known for its excellent thermal, chemical, and mechanical properties. It is a type of polymer that offers high heat resistance, chemical resistance, flame retardancy, and dimensional stability.

PPS materials are often used in industries where these properties are crucial, such as automotive, aerospace, electrical and electronics, and industrial applications. Some common uses of PPS material include engine components, pump parts, electrical connectors, semiconductor components, and various parts requiring high temperature resistance and chemical resistance.

Download

-

PPSGF40 TPS80G8 NT BK.pdf

Download PPSGF40 TPS80G8 NT BK.pdf